Copyright©2019, TUTRIC, All Rights Reserved 津ICP备11002748号-1 Powered by www.300.cn

Scan into

Mobile version

Scan into

WeChat public account

Chapter Three:Factors of tire service life

Construction machinery tire is an important part of mine and port vehicles. It has high load capacity, high torque capacity, high adhesion capacity, buffering performance and durability to meet the use requirements of vehicles. These properties are determined by the structure, specification, pattern, raw materials and process conditions of tires, and have certain use regulations. In use, with the change of service conditions, such as air pressure, load, vehicle speed, matching and other factors, some performance of tire also changes. Therefore, according to the requirements of the vehicle, combined with the changes of tire performance, the relationship between the two should be adjusted in time to adapt, which will be able to improve the service life of the tire and reduce the use cost.

1.Selection and installation of tires.

The correct installation of the tire is directly related to the life of the tire, especially when renewing the tire. Tires with different types and patterns must not be mixed arbitrarily due to the actual size and load capacity of each tire. For twin tires, improper matching will cause uneven load distribution. Larger diameter tires bear more load, resulting in excessive heat generation and undue damage. Smaller tires can slip and scrape on the road, causing rapid wear on the crown. To prevent this from happening, you should avoid putting together different brands, different structures (forbidden to mix coaxial radial tires and bias tires), and tires with very different outer diameters. For side-by-side twin tires, the allowable tolerances for the tire diameter are shown in the following table (the tolerance of the tire diameter must not be resolved by adjusting the inflation pressure).

|

Section width |

Maximum tolerance |

|

|

Diameter |

Circumference of circle |

|

|

—8.25 |

6mm(0.25inch) |

20mm(25/32inch) |

|

9.00—14.00 |

13mm(0.50inch) |

40mm(50/32inch) |

|

16.00—18.00 |

19mm(0.75inch) |

60mm(75/32inch) |

|

21.00— |

25mm(1.00inch) |

80mm(100/32inch) |

2.Inflation and pressure

1)

Nitrogen has been widely used as a method to prevent tire self ignition at home and abroad. Tire self ignition is caused by tire overheating, which is caused by many aspects. Excessive braking and rim heat transfer to tire will generate a lot of heat when the tire is running under the condition of serious air shortage. At this time, if the ply is seriously damaged, a lot of cold air will be filled, It may cause sudden burst and spontaneous combustion of tire, while nitrogen is an inert gas, which will not support combustion. When nitrogen is filled, the durability of air pressure will be improved, the matrix will not be nitrided, and the rust of rim will be solved. The tire maintenance manual of Goodyear tire company in the United States States States States that "if you refuse to use the nitrogen charging method recommended by the manufacturer of engineering vehicles, you will assume that you hereby acknowledge the following facts. Under the recommended working conditions, users do not use nitrogen charging instead of air charging, resulting in personal injury or property loss, Goodyear tire company and its Neither the Trustee nor the employee shall be responsible for this. " Thus, the importance of nitrogen filling can be seen. Therefore, we suggest that all units with permitted conditions should fill nitrogen, especially giant engineering tires, and try not to use compressed air.

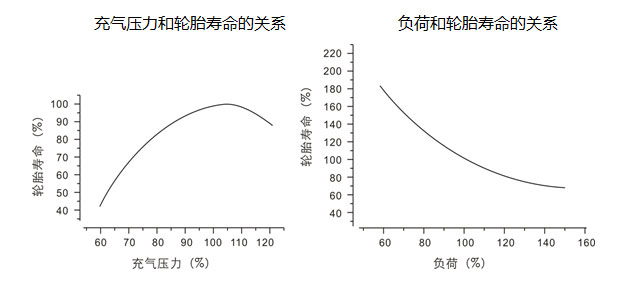

2) Air pressure

{1}High inflation pressure

On the one hand, too high inflation pressure will reduce the ground area of the tread, reduce the floatability and traction performance, and increase the energy consumption of the engine; on the other hand, too high internal pressure will also make the rubber and cord over stretched. These factors cause the following tire damage:

a) Excessive swelling of the driving surface increases the ground pressure in the center of the tread and causes excessive wear of the tire crown.

b) Reduce the cushion effect of ply on the impact, not resistant to the impact cutting and stabbing of the bad road surface, easy to cause early tire damage.

c) Excessive pressure is applied to the bead area, increasing the potential risk of bead burst.

d) Too high air pressure causes poor shock absorption performance, resulting in damage to vehicle chassis components.

e) It is easy to slip when driving on the muddy road, which often leads to continuous circumferentially cutting when encountering sharp objects.

f) Driving is not comfortable and the vehicle is bumpy.

{2} Low inflation pressure

When the inflation pressure is insufficient, it will directly cause the tire to run under overload, resulting in the tire body to become soft, the tire body to be excessively bent, deformed and hot, and the tire cord to be excessively tired, etc., causing the following permanent damage to the tire:

a) Large deformation and heat generation of tire lead to early damage of tire.

b) It is easy to cause radial crack, void and delamination.

c) Accelerate ply fatigue and breakage.

d) As a result, the tire moves with the rim, the inner tube tire is easy to cut off the inner tube valve, and the tubeless tire leaks.

3)Overload

The standard recommends the maximum load of each specification tire under different operating speeds. For better use of tyres, the recommended maximum load should not be exceeded. If the working load exceeds the specified load of the tire, the use of higher level tire shall be considered, and overload driving will cause the following losses to the tire:

a) The deformation and heat generation of the tire increased, which resulted in the tire delamination and even burst.

b) Tire deformation is large, which causes ply delamination and breakage and cord breakage, which makes tire easy to burst.

c) The relative slippage of tire surface increases, and the abrasion increases sharply.

d) The tire bead is overloaded and the toe rim is easy to wear.

e) Increase the ply tension of the carcass, there is a risk of tire burst, especially when impacted.

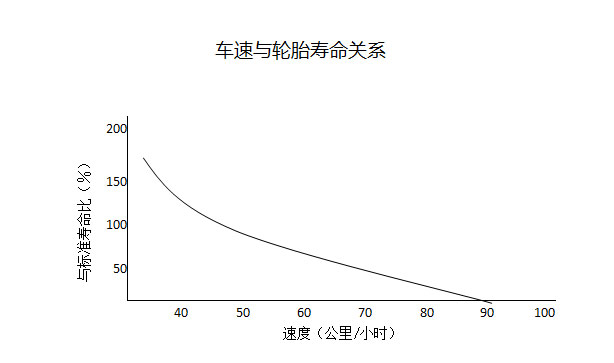

4 Speed

In order to use work machinery and tires efficiently, safely, and economically, it is necessary to drive transport and port vehicles at an appropriate speed range. The average speed of a tyre is limited by the ton-km per hour of tyre used.

Excessive driving speeds can cause:

a) Excessive heat generation inside the tire causes thermal delamination.

b) The number of sudden braking increases, and the bead is subjected to large forces. At the same time, it must withstand the heat from the brake drum, which causes bead wear, delamination and bead burns.

c) A sharp turn causes abnormal and rapid wear of the tire. At the same time, the tire is biased and the bead is damaged.

d) When it encounters hard objects on the road, it is easy to produce tread cracks and impact blasts.

e) The turning radius is too small to accelerate tread wear.

f) When the port gantry crane is working, the number of jogs is excessive, which causes the tire load on the loading side to increase, which may easily cause the carcass to become empty and delaminate.

6. Vehicle driving

Driver is important role in the service life of vehicles. Excellent drivers can use and maintain tires correctly, and explore a set of reasonable use methods in practice to better extend the service life of tires. However, unreasonable driving and use of tires may also seriously shorten the service life of tires. In order to use the tire more effectively, the driver should pay attention to the following points:

1) Avoid sudden starting or sudden braking.

2) Do not drive on the road shoulder.

3) Slow down when turning.

4) Maintain reasonable air pressure.

5) Regularly check whether the tires, rims and valves are normal.

6) Repair any defective tires immediately.

7) Avoid driving in greasy dirt places.

8) Put the cargo on the center of the car deck to prevent partial load.

9) When driving the gantry crane in the port, the positioning shall be accurate and the number of inching vehicles shall be reduced.

7.Tire temperature

In the process of vehicle driving, the tire temperature increases because of stretching, compression and friction. Too high temperature is easy to increase tire wear and even tire blowout.

The tyres selected for vehicles shall be selected according to the service conditions and TKPH value of tyres:

The working temperature of the tire directly affects its service life, and the heat generation in the tire is caused by the deformation stress of the tire and the hysteresis loss. The amount of heat generated is not only related to tire size, level and structure, but also related to tire load, air pressure and operation cycle. The total rising temperature depends on the impact of continuous operation time and environmental test. The TKPH value of tire reflects the above-mentioned factors, which indicates the heat generation limit of tire, and is also an index used to limit the working condition of tire. The test shows that the wheel When the tire temperature exceeds a certain limit, the tensile strength of its carcass ply drops sharply, resulting in rubber aging and deformation. Therefore, foreign regulations stipulate that the service temperature of nylon cord tire shall not exceed 107 degrees. In order to prevent the strength drop caused by excessive temperature from causing rapid tire damage, a load speed value corresponding to the thermal limit value of a tire is specified Its TKPH value.

TKPH operation value can be calculated by the following formula:

TKPH operation value = average tire load x average running speed of tire per working day.

Where: average tire load = {unloaded tire load (ton) loaded tire load (ton)} / 2

Average speed of tires per working day = round trip distance (km) x times of back and forth / total working time (total time from the first shift to the end of the last shift)

8. Tire maintenance

Timely transposition, proper pattern selection, daily maintenance, regular inspection of tire pressure, timely repair and frequent digging of stones and foreign matters in tire pattern are all important factors to prolong tire life.

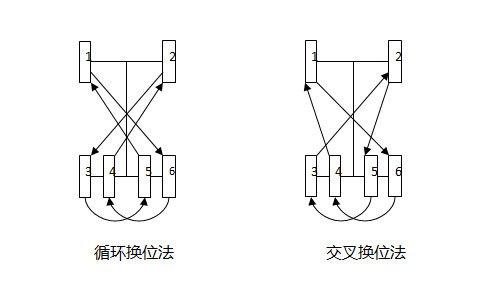

After a period of use, due to the influence of road camber, braking, tire assembly position and other factors, the tread wear will be greatly different. Therefore, it is necessary to conduct timely transposition assembly, so that each tire can take turns at each position, and the load borne by each tire is roughly the same, so as to solve the problem of tire eccentric wear and extended service life Question. There are two common methods of tyre transposition: "cross transposition" and "cycle transposition". However, once it is selected and determined, it shall be carried out according to the original determined transposition method each time, and shall not be changed halfway. The above transposition method can be adopted for the vehicle with tire replacement; when the new and old tires are mixed, the new tires or better tires are fixed to the front wheel, and the old tires or retreaded tires are fixed to the rear wheel, the left and right transposition, internal and external shift and other methods are adopted. When the original rolling direction is changed after transposition, the reverse side of the tire shall be placed (i.e. the loading position and rolling direction shall be adjusted), which is not only a measure to reduce or even eliminate the eccentric wear chamfering of the tire and the excessive unilateral fatigue of the shoulder, but also a way to extend the service life of the tire and improve the retreading.

9.Road conditions

10.If the vehicle is driven on the gravel road or under the bad road conditions for a long time, the service life of the tire will certainly be reduced. When driving on an uneven gravel road mining area, because of the exposed sharp stones or sharp stones on the side of the road, it is very easy to damage the tires, so the road should be selected to control the speed to prevent the tire from blasting damage. The maintenance and cleaning of roads should be strengthened to ensure the normal operation of vehicles.