Copyright©2019, TUTRIC, All Rights Reserved 津ICP备11002748号-1 Powered by www.300.cn

Scan into

Mobile version

Scan into

WeChat public account

Chapter Two:Tire usage

Section One -- Preparations before the installation

a. Tube type tire

a) The inner tube and flap of the same size as the outer tire must be selected.

b) Before installing the tire, check the tire if has any debris inside, and do the necessary cleaning work, remove rust, check the rim parts for deformation and cracks.

c) Check whether the hexagon nuts at the root of the inner tube valve mouth is tight, then fill a certain amount of air pressure, check whether the inner tube is leaking, especially pay attention to the valve nozzle root (better using water).

d) Before the installation of the inner tube in the outer tire and the inner tube surface coated with talcum powder, in order to facilitate the inner tire stretching and in use of the friction of the inner and outer carcass, reduce the heat of the carcass.

e) When installing the inner tube, the inner tube valve nozzle should be placed in the center of the rim valve nozzle hole.

f) the role of the flap is to protect the inner tube from rim and tire toe damage, before loading to check the flap with no cracks and valve nozzle damage.

b. Tireless tire

a) Tubeless tire before installing on the rim, check the tire cavity for debris, and do the necessary cleaning work, check the tire airtight layer for damage, tire in the lifting of any damage, if there is damage must be repaired after but used.

b) Check the rim parts for cracks and rust.

c) Check that the seal is intact before installing the tire, all seals are disposable, and all used seals cannot be used again.

d) When installing the tire to protect the tire mouth not to be damaged, tire after loading to check the tire port and rim and then the part of the leak, at the same time to check the valve core and valve nozzle root with the rim in conjunction with whether the air leakage.

e) If the vehicle is found to be a manufacturing problem before the factory needs to contact to solve the problem before it can be put into use.

Section Two -- Management in use

a. Tire managers should do the following

a) Tire loading at the same time to fill in the tire use card (e.g. Appendix I), in addition to filling in the card requirements, but also need to indicate the appearance of the tire, whether there is damage and the size of the damage site, in the future use of the problems should be filled in the card, such as: damage, repair or renovation, all stages of driving mileage, hours, until the end of the end.

b) Air pressure must be checked frequently, and maintain in the standard pressure, when the first inflatable must be filled with standard air pressure, in operation of the air pressure has increased, mainly due to the tire operation of heat to promote air pressure increase, which is no major barrier to tires, not to lower the pressure, if found air pressure is insufficient, should be timely inflating.

c) If the tire is found to have a small drum, can be punctured in time, the exhaust can extend some service life.

d) When serious damage on the carcass is found, it is necessary to replace in time to ensure the vehicle and personal safety.

e) Remove the tire when it is found to be severely out of air, check if the cord has been damaged due to the lack of air, and any tire that is damaged can no longer be inflated.

f) If the tire is often out of air, carefully check all parts of the tire for air leakage (can be applied with soap water to the tire surface inspection). Check the root of the valve and rims and parts of the cracks, find out the cause of the leak and eliminate it immediately.

g) Before removing the tire from the car, check the rim and the pressure ring for cracks, if damaged, first put off the tire internal pressure and then remove, to avoid tire removal when the tire is shaken, sudden explosion caused work casualties.

h) Wear a hard hat before check the air pressure, and protective glasses, check the air pressure when the face is not right to the valve, due to the pressure inside the tube is greater, be careful blowing out of dust and sand and moisture, etc. , damage the eyes and face during measuring air pressure. Check the air pressure with soap water or feel whether the air leakage, and then put on a dust cap.

i) When the twin-tires are installed, the valve must be staggered, do not lead in the same rim hole, in order to facilitate the inflation and measurement of air pressure, the inner tube valve to add an extension tube, in order to measure the internal tube pressure.

j) Construction tires, especially large-scale one, because most of them are tubeless, in order to make tire and rim close cooperation, the ring and rim between the amount of profit, the size of its excess is increased and decreased with the size of the tire, the manufacturers of excess is not consistent, from 3.2mm to 7.8mm. It is more difficult to remove an over-profit tire, to rely on the force of machinery, that is, tire removal machine, with the dismantling machine to remove the tire not only easy to remove, but also to avoid the damage of the tire and rim, if the two-wheeled tire with fire, can be repaired and refurbished after the scrap, but also cause the wheel deformation rim, after the fire There is a lot of residue on the rim, which also affects the sealing performance of the tire.

k) Put tread into the right direction, such as when installing the drive wheel, in the direction of the pattern; for passive wheel, can be installed in the opposite direction of the tread, which can reduce the rolling resistance.

b. Driver notice

a) The driver should check the air pressure before leaving the car to meet the requirements, driving (or work) to observe the changes in tires, air pressure, damage and other conditions, after the shift to check the air pressure and tire damage, fill in the shift record, the driver should always pay attention to tire changes. If you find a large damage, contact the management personnel in time. When the tire damage, should immediately stop the work, back to the workshop to change the tire, never allow to force driving, resulting in damage to another tire.

b) Drivers should choose better work sites and driving routes when working and driving (referring to mines, construction sites) to avoid stones stung by tires.

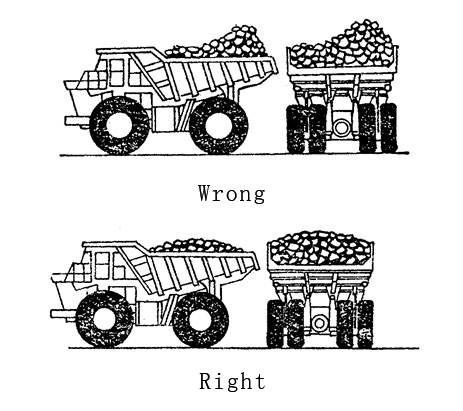

c) Loading and unloading should be installed in the middle of the vehicle box, so that the loading cloth is reasonable, load balanced distribution, to avoid local overload, so that individual tires overload driving.